Operational Benefits to Brands on Lucid Green Platform

Undoubtedly, most brands are seeing the wave of retailers requiring pre-ticketing of critical product information on shipments being received into their dispensaries. While this helps to dramatically streamline retailer operations, such that they can save significant time and money, many brands often wonder where they can derive benefit from this step. If a brand does not have the right tools at their disposal, the benefits of pre-ticketing in the supply chain will be very difficult to realize. Lucid Green’s platform allows brands to adhere to dispensaries policies, but also ensure they maximize benefits just like retail!

It is important to understand that the idea of pre-ticketing solves one major issue for the ENTIRE cannabis industry – a drastic reduction in time of “truck-to-shelf” inventory management. Currently, document management of CoAs, METRC tagging, and incomplete product information causes a wave of challenges when retailers attempt to receive products. While retailers feel the brunt of the pain from a labor and cost perspective to manage this at their stores, products that brands believe to be on shelf are often left sitting in storage and work-in-process inventory until all proper METRC, quality, and product level information can be obtained. This can lead to a host of challenges on the brand side, from lost revenue to product aging in the store. Due to the lack of connectivity across the supply chain, solving these problems is often a manual process between the retailer, distributor, and brand that can become hectic and challenging to manage.

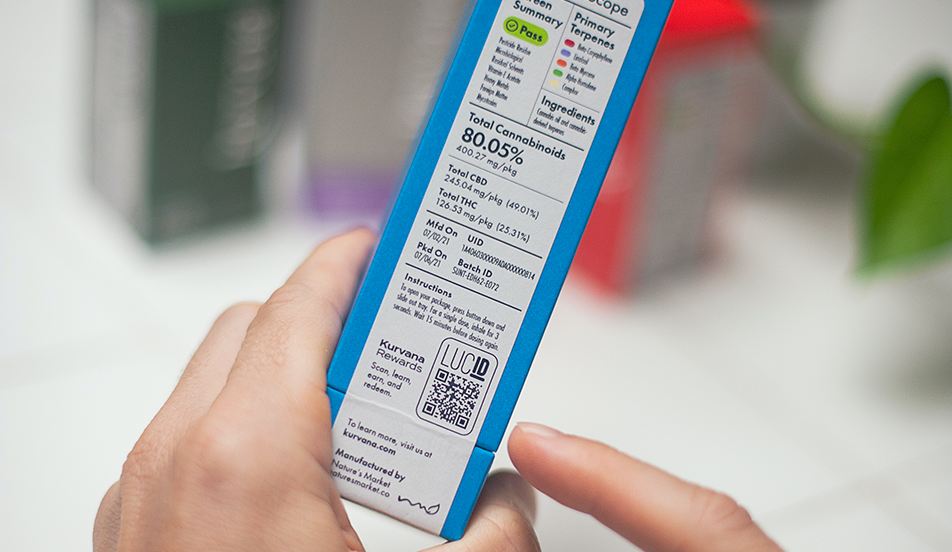

Before diving in further to how Lucid Green’s platform inevitably solves for this issue, it starts with how the brands can utilize Lucid Green to make sure proper information is attributed to their products. When implementing Lucid Green, each product produced by a brand has a unique QR code called a LucidID embedded directly with the regulatory label, with no added sticker in production. This LucidID now gives EACH ONE of the units (eaches) the following operational benefits:

1. Critical product information embedded with the individual package – all critical product information you normally cannot fit on a label now lives within this QR code. This can also be dynamically updated to ensure all information is appropriate and correct at various points in the supply chain and at retail.

2. CoAs can now be directly attached to this individual unit - Lucid Green has partnered with laboratories and LIMS across California to allow for CoA information to seamlessly pass to the individual product. This allows for individuals printing labels to also have the information automatically added to their label templates prior to printing, saving 5-10 minutes for every CoA and eliminating manual entry issues.

In order to ensure seamless passing of this product information at distributors and retail, Lucid Green has rolled out its LucidCapture solution to further optimize the cannabis supply chain. With LucidCapture, each sell pack, prior to being packaged, is affixed with an additional agnostic QR Code, known as a CaseID. Utilizing a simple MDM scanner, brands can take each of their packages with LucidIDs and scan them to the CaseID for a specific sell pack. This allows for all of the eaches (and all of their critical information) in this sell pack to be attributed to this one CaseID.

To ensure this step is managed appropriately within a manufacturing or distribution operation, Lucid Green offers this with both a “trigger” scanner method and a “continuous” scanner method to suit all operational needs. With less than 0.5 seconds per scan, brands can now ensure their products are pre-ticketed for simplicity of moving through distribution and retail, AND they add a critical quality checkpoint of each item prior to shipping. This ensures their products will be in the best possible condition when they reach retail. Most critically, Lucid Green has given the ability to complete direct integrations with distribution ERP systems, both large and small, to allow for METRC information to be updated with this CaseID. This step brings us back to the largest benefit of the entire Lucid Green platform for brands AND retailers: the reduction in “truck-to-shelf” inventory management time.

With all critical regulatory information, product information, and quality information now associated with a CaseID on each sell pack, a retailer simply needs to scan a CaseID via the LucidRetail app to ingest this into their inventory. The simple scan saves brands from having to attach and manage quality and invoice data with every order and every batch going into retail. This saves brands up to 2 hours PER DAY on managing this document flow to retailers based on orders. In addition, the platform eliminates the risk of manual error in the processing of all this data. From a cost perspective, many of these roles also tend to be higher admin/salary roles, so finding opportunities to utilize this labor in more efficient ways can be invaluable to many brands looking to streamline operations!

In summary, a brand gains the following efficiencies using the Lucid Green platform:

· Eliminate manual entry of batch data prior to printing regulatory labels, saving approximately 5-10 minutes per entry.

· Pre-ticket to a sell pack/case all critical information for each individual product, with a sub 0.5 second per scan to complete.

· Eliminate significant document maintenance of upto 2 hours per day in admin costs by having CaseIDs seamlessly ingested into a retail inventory system.

· Significantly reduce the time of “truck-to-shelf” inventory management ensuring brands are able to meet sales and revenue targets in their expected time frame.

If you have further questions or would like to see how Lucid Green can directly benefit YOUR operation, please reach out to me, SVP of Operations, Jake Haworth, for more information.

Schedule a demo here.